Hyundai Polytech is establishing a 2025 Safety & Health Policy under the slogan "Change & Innovation for the Next Generation."

We are building a safety & health strategy through major goals of strengthening safety & health management, checking and improving harmful and dangerous factors, and complying with safety & health-related laws and regulations.

Safety & Health Management Education and Awareness Enhancement

Set Safety & Health KPI by Organization

Expand Management Supervisor Authority/Responsibility

Achieve 100% Zero Major Accidents

Conduct Risk Assessment

Implement Safety Insensitivity Awareness Improvement Education

Zero Accidents through Facility Inspection

Monitor Legal Updates Continuously

Improve Legal Awareness Level through Company-wide Law Distribution

Strengthen Partner Safety Inspection

Thorough MSDS Management

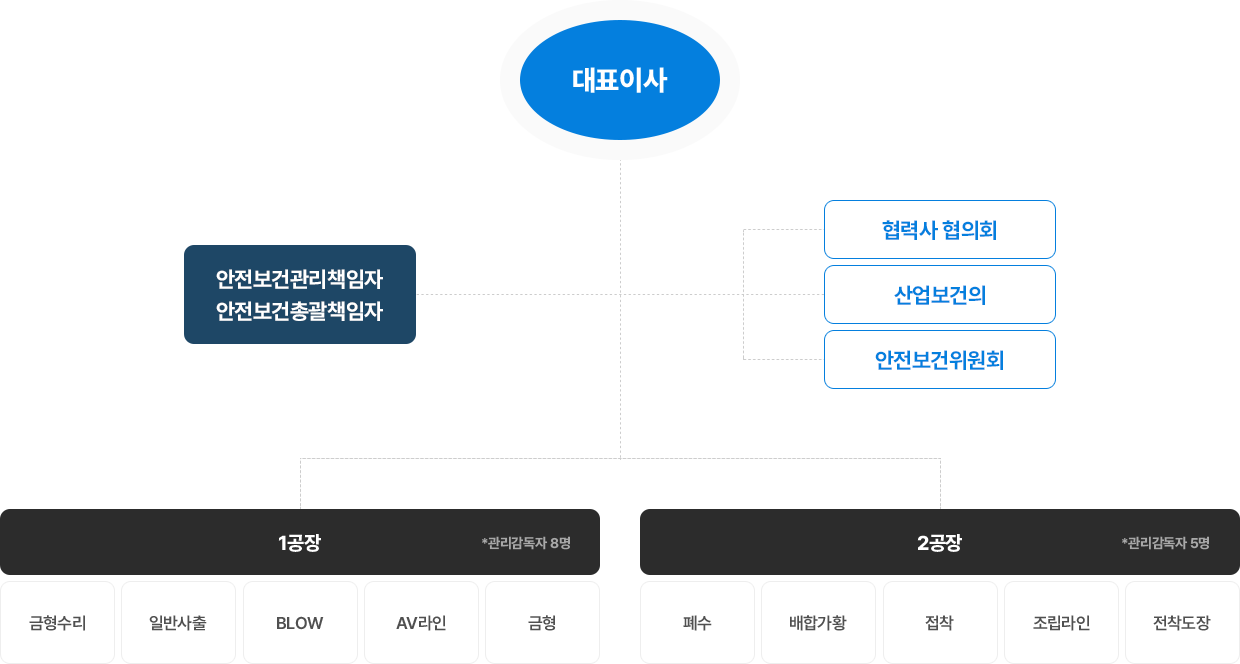

Hyundai Polytech has a separate safety & health management organization, and three organizations including the Industrial Safety & Health Committee, Partner Council, and Industrial Health Doctor,

along with 13 management supervisors, are working to improve Hyundai Polytech's safety & health.

Hyundai Polytech is strengthening safety & health management by establishing a detailed 2023 Safety & Health Management Implementation Plan. Top management clearly presents the company's safety & health policy, goals, and will for safety & health performance improvement, and posted the safety & health policy at the beginning of the year so all members can share the safety & health policy at the beginning of the year. Additionally, to fully fulfill Hyundai Polytech's responsibility for safety & health, we have organized a safety & health management organization that shares the review, planning, and execution of industrial accident prevention measures and assigned appropriate roles by organizing a safety & health management organization chart. We established an Industrial Safety & Health Committee to protect employees from harmful factors and create a comfortable work environment through workplace environment measurement.

Hyundai Polytech aims to identify harmful and dangerous factors in advance through annual regular risk assessments, estimate risks in advance, and establish countermeasures according to the magnitude of the risk. We planned and implemented ad-hoc evaluations for new equipment installation, new process introduction and changes, and when accidents occur. We conduct joint inspections twice a month for each process to prevent accidents in advance, and protect employees from harmful factors and create a comfortable work environment through work environment measurement, including harmful chemical substance use processes, injection molding machine and vulcanization line noise measurement.

Hyundai Polytech improves members' safety & health awareness through safety & health education. We conduct 10-minute safety education before work changes, regular safety & health education for 2 hours monthly, and also conduct special safety & health education, safety & health management responsible person education, and management supervisor education according to targets to provide education appropriate for each job and responsibility.

| Category | Unit | 2020 | 2021 | 2022 |

|---|---|---|---|---|

| Total Work Hours | Hours | 395,568 | 387,100 | 443,104 |

| Lost Time Injury Cases (LTI) | Cases | 1 case/209 days | 0 | 1 case/266 days |

| Lost Time Injury Rate (LTIR) | Cases/200,000 work hours | 0.5 | 0 | 0.45 |

| Total Recordable Injury Cases (TRI) | Cases | 1 | 0 | 1 |

| Total Recordable Injury Rate (TRIR) | Cases/200,000 work hours | 0.5 | 0 | 0.45 |

| Fatalities | Persons | 0 | 0 | 0 |

| Fatality Rate | % | 0 | 0 | 0 |